Built for Cannabis Professionals

Who Don't Get Second Chances

TheBOX® was designed for real-world cannabis operations—where failed tests, terpene loss, and remediation shortcuts carry real cost.

Not emergency fixes. Not remediation shortcuts.

Built for operators who require repeatability, auditability, and margin protection.

Three Operational

Challenges

Contamination Risk

Microbial contamination can result in batch failures at state testing facilities, making post-harvest pathogen control a structural requirement

Moisture Imbalance

Inconsistent levels affect product structure, shelf life, and terpene preservation

Lot-to-Lot Variation

Without standardization, each harvest produces variable outcomes

These issues directly impact testing compliance, product quality, and operational predictability

Built for

Professionals

Licensed Cultivators

& Growers

Consistent microbial compliance without degrading terpene profiles.

Post-Harvest

& Processing Teams

Repeatable in-process control that protects margin and quality.

Quality & Compliance

Managers

Auditable kill step with documented process parameters.

Multi-Site Operators

& MSOs

Standardized operations across facilities with predictable outcomes.

Professionals operate on outcomes,

not expectations.

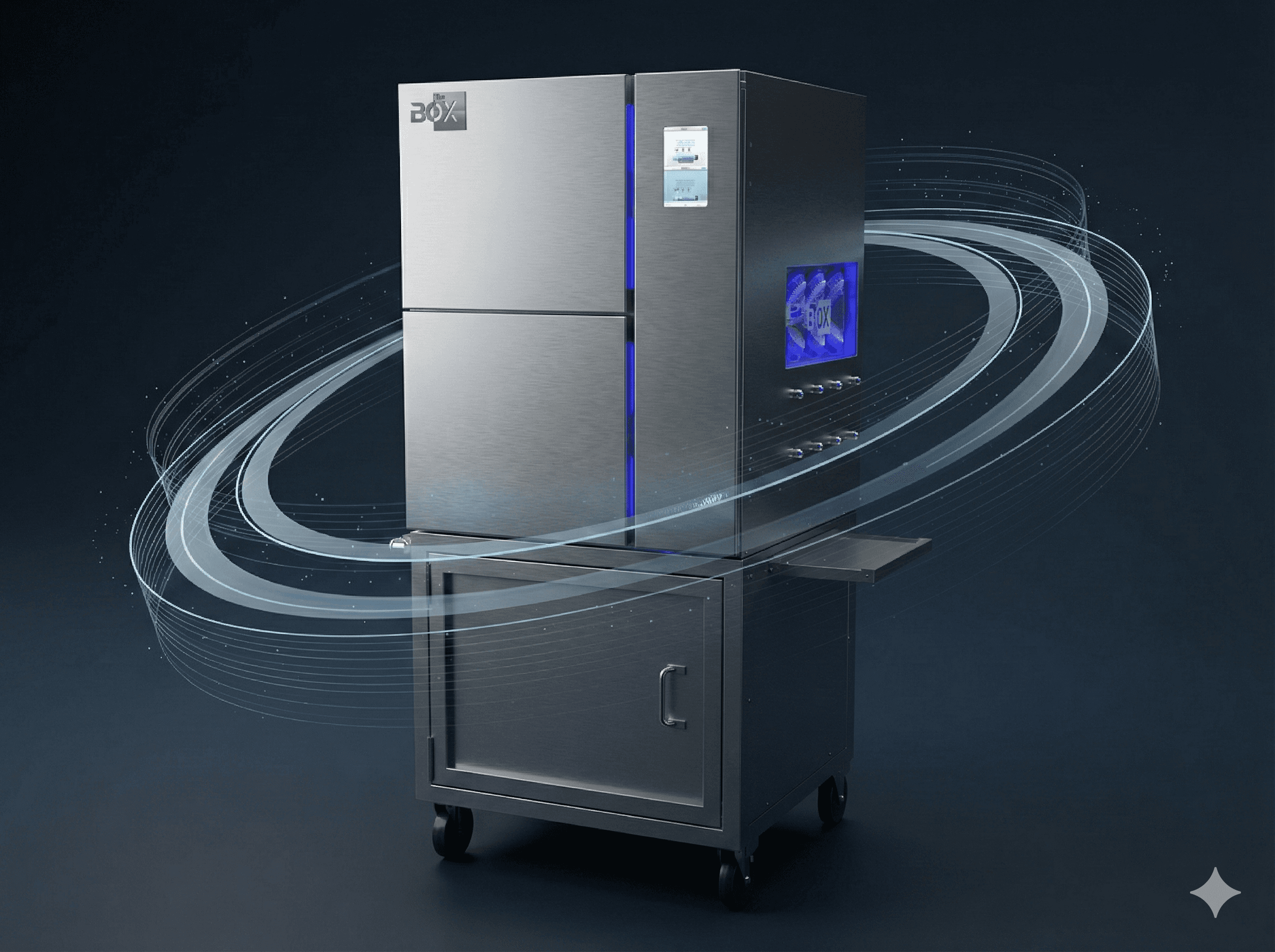

A Tool Designed for

In-Process Control

Built for operators who understand that process control, repeatability, and margin protection are operational requirements—not optional.

Purification

Reliable kill step, repeatable, auditable.

Engineered Reactive Oxygen® sterilization has demonstrated consistent pathogen reduction while preserving cannabinoid and terpene profiles—documented across repeated batch processing.

Learn moreRehydration

Controlled moisture correction, not guesswork.

Restores cannabis flower to target ~12% moisture equilibrium through controlled vacuum conditions—maintaining structure and terpene integrity without additives.

Learn moreInfusion

Intentional differentiation, not spray-on hacks.

Optional controlled infusion capabilities support intentional product differentiation through terpene or cannabinoid enhancement—integrated into the same controlled process.

Learn moreProcess Control,

Not Promises

TheBOX® integrates between drying and packaging as a standardized process step—not an emergency remediation tool. Each cycle follows documented parameters with repeatable conditions.

Adjustable sterilization parameters—vacuum pressure, exposure time, Reactive Oxygen® concentration—enable controlled processing while preserving product composition.

Margin Protection

Failed tests cost more than equipment. TheBOX® supports regulatory confidence through predictable, repeatable outcomes—protecting both quality and margin.

Repeatable Consistency

Batch-to-batch reliability that reduces variability and protects product integrity.

Quality Preservation

Demonstrated terpene and potency preservation—maintains product value through controlled processing.

Compliance Confidence

Documented process parameters support auditable compliance without remediation risk.

From the Field

What Professionals Say

Hear directly from cannabis professionals using TheBOX® in their operations

Professionals trust TheBOX® because it delivers control, not promises.

Every feature exists to protect margins, maintain compliance, and standardize output. The science explains why it works. The system delivers the results.

Process Control for Regulated Cannabis Operations