Technology Foundation

Sterilization Science

Non-ionizing methodology derived from regulated biological processing.

The Technology

Vaporized hydrogen peroxide delivered under extreme vacuum enables vapor-phase diffusion throughout complex biological material—penetrating beyond surface boundaries into the material matrix.

The controlled vacuum chamber environment ensures consistent distribution and contact. Validated parameters govern exposure duration, concentration, and environmental conditions—producing repeatable, documented outcomes.

Post-process decomposition to water vapor and oxygen leaves no residual compounds on processed material.

What It Is Not

—Ionizing radiation

—Ozone-based processing

—Thermal sterilization

—Ambient fogging or misting

—Surface-only decontamination

What It Is

—Controlled vacuum sterilization

—Vapor-phase diffusion process

—Deep penetrative exposure

—Low-temperature compatible

—Decades of validated application

Foundation

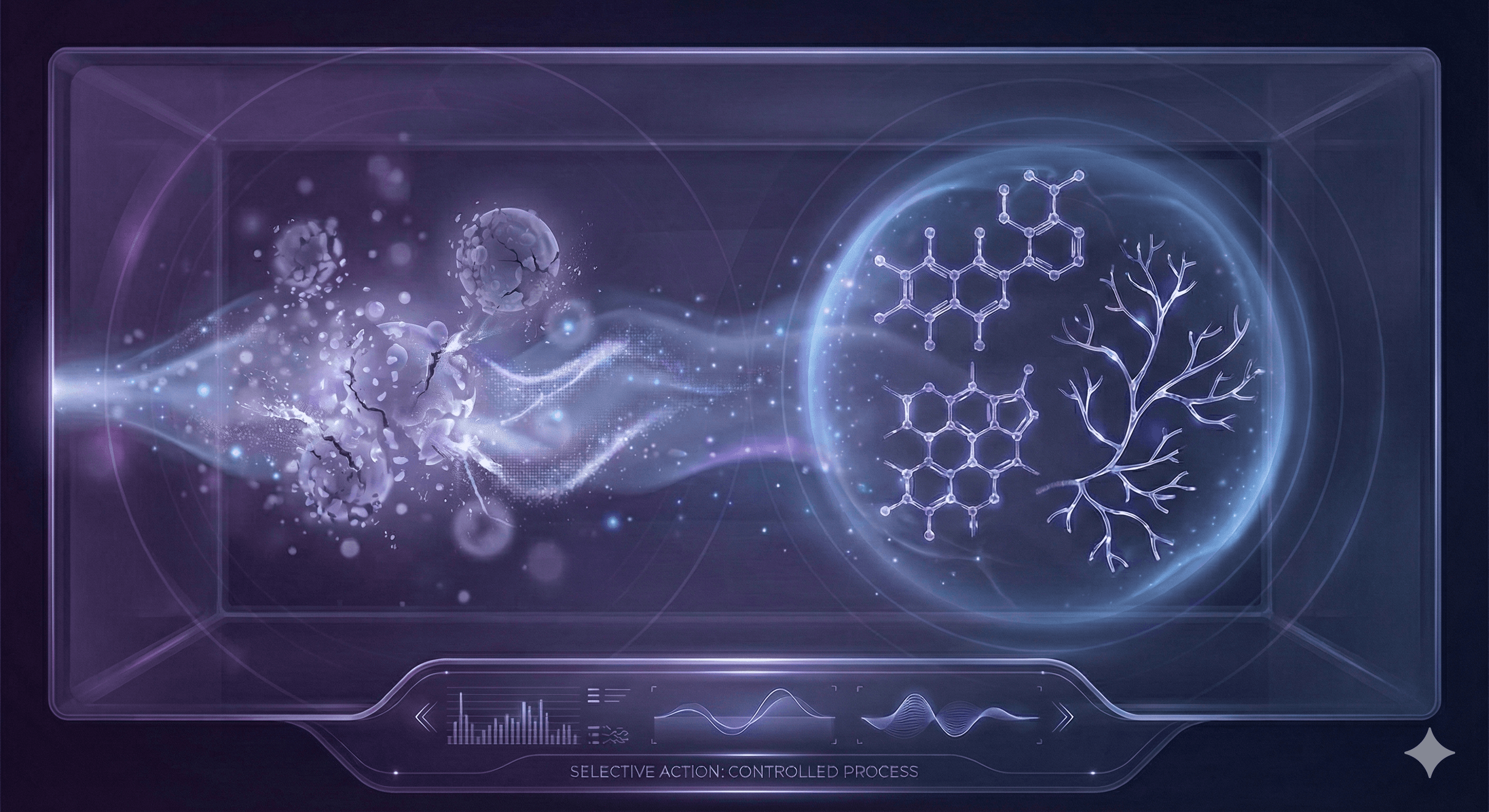

Non-Ionizing Process

Microbial disruption without ionizing energy—material chemistry remains unaltered by the process.

Preservation

Material Integrity

Selective action—parameters that microorganisms cannot tolerate but sensitive compounds can.

Validation

Documented Efficacy

Log reduction measured against scientific standards. Repeatable parameters. Consistent outcomes.

Why Non-Ionizing Matters

Ionizing Radiation

Gamma rays, X-rays, and electron beams carry enough energy to break molecular bonds indiscriminately. Effective for sterilization, but can alter material chemistry in unintended ways.

Vacuum-Enabled VHP

VHP delivered under extreme vacuum achieves microbial disruption through deep vapor-phase diffusion—without the penetrating energy that can alter material chemistry. Molecular structure remains intact.

Selective Action

Microorganisms and plant-derived compounds respond differently to this process. System design exploits this differential susceptibility.

Differential Susceptibility

Microbial structures are vulnerable at concentrations and durations that do not significantly impact cannabinoid or terpene chemistry. This selectivity is the basis of process design.

Parameter Control

• Exposure duration: Managed to achieve efficacy without excess

• Concentration: Maintained within validated range

• Environment: Temperature, humidity, and pressure regulated

Scientific Background

Established Use

VHP sterilization is selected when material preservation, molecular integrity, and residue-free outcomes are non-negotiable. For decades, it has served regulated industries where heat, steam, or ionizing radiation are contraindicated—either because they would damage sensitive materials or compromise functional performance.

• Medical device sterilization: Electronics, polymers, optical components, sensors, and battery-containing devices that cannot tolerate thermal or ionizing methods

• Human tissue processing: Allograft tissue prepared for clinical transplantation, where irradiation or heat would compromise biological structure

• Pharmaceutical manufacturing: Cleanroom and isolator decontamination in environments requiring validated sterility without residue

• Hospital environments: Operating suites, patient rooms, and critical care areas where rapid turnaround and material compatibility are required

When the most delicate sterilization challenges arise—across healthcare, pharmaceutical, and advanced manufacturing—VHP has become the established methodology of choice.

Cannabis Application

Cannabis presented a constraint-driven engineering problem. Dried flower is a moisture-bearing, chemically volatile botanical material—conditions that commercially available VHP systems are not designed to accommodate. Standard VHP equipment will not initiate in the presence of meaningful residual moisture and lacks the programmability required to adapt to moisture-bearing biological loads.

The core technology was originally developed by PuroGen, the parent company, for human tissue sterilization in the transplant industry. Human allograft tissue presented similar preservation constraints: moisture sensitivity and the requirement to preserve osteoinductivity and osteoconductivity—biological properties essential to surgical outcomes.

The parallel between preserving biological performance in tissue and preserving terpenes, cannabinoids, and moisture behavior in cannabis informed the engineering approach. TheBOX® was purpose-engineered to operate in moisture-bearing biological materials using controlled vapor-phase diffusion under extreme vacuum—achieving microbial reduction alongside preservation, not at the expense of it.

Adaptation of this technology to cannabis began in 2015. More than 100 units have since been deployed across U.S. and international markets.

Reactive Oxygen®

Reactive Oxygen® is the branded name for the proprietary reagent and process framework integrated within TheBOX® system. It does not refer to uncontrolled reactive oxygen species and should not be interpreted as free-radical chemistry.

Within the Reactive Oxygen® framework, reactive activity is intentionally generated, transient, and spatially constrained—a function of defined process conditions rather than ambient chemical behavior. Microbial reduction is system-mediated: governed by chamber architecture, parameter control, and exposure boundaries—not by chemical aggressiveness alone.

The result is predictable, repeatable sterilization outcomes with material preservation as a design constraint, not a trade-off.

Non-ionizing

No material-altering radiation

VHP-based

Controlled reagent delivery

No residuals

Decomposes post-process

Deep diffusion

Vacuum-enabled penetration

Material preservation

Compound integrity maintained

System-mediated

Architecture-governed outcomes

Validation Philosophy

Demonstrating that a process consistently produces intended outcomes under defined conditions.

Log Reduction

Microbial reduction expressed in logarithmic terms—1-log represents 90% decrease; 3-log represents 99.9%. A scientific convention for standardized comparison.

Repeatability

Process parameters controlled with sufficient precision that the same inputs yield the same results across cycles, units, and facilities.

Documentation

Cycle parameters, lot identification, and process conditions captured and retained—the foundation of defensible claims about outcomes.

Consistency

System design, automation, and operator controls that translate validated parameters to real-world consistency.

Scope of Validation

Documented evidence across system efficacy, safety, and operational constraints.

System Efficacy

Biological Indicator Validation

—Industry-standard biological indicators

—Empty chamber testing (material-independent)

—~1,000,000 CFU (~6-log) reduction per cycle

—Demonstrates system capability

Internal Field Testing

—Internal plating within licensed operations

—Observed reductions: ~450,000 to 1,000,000 CFU

—Operational confirmation, not lab certification

—Material-dependent outcomes expected

Regulatory Testing Constraints

THC-containing cannabis cannot be sent to most accredited microbiology institutions. Controlled substance handling restrictions limit conventional third-party validation pathways. This structural constraint applies industry-wide and is not unique to any single manufacturer or system.

Material Variability

What Varies

—Flower density, porosity, internal structure

—Diffusion-dependent behavior in vapor-phase processes

—Heterogeneous biological material

What Does Not Vary

—System capability is constant

—Process parameters are governed

—Observed outcomes reflect material properties

Safety Validation

Human & Environmental

No residual compounds; decomposes to water and oxygen

Product Safety

Material integrity preserved; no ionizing energy

Biological Safety

Process does not alter molecular chemistry

Declared Validations

Third-party studies conducted under recognized standards and protocols.

The process is validated. The parameters are documented. The outcomes are repeatable.

This is the scientific foundation. TheBOX® is the system that implements it for regulated cannabis operations.

Process Control for Regulated Cannabis Operations